Harness the power of positive robot impact! Whether you have a single robot or a fleet of them, Yaskawa is committed to helping customers enhance their competitive edge. A simple and effective approach for doing this is by highlighting your successful integration of Yaskawa robots through a case study or testimonial. By sharing the solutions used and the outcomes achieved, your company can be showcased as a forward-thinking industry leader to the markets you serve.

Filter by Application

Filter by Industry

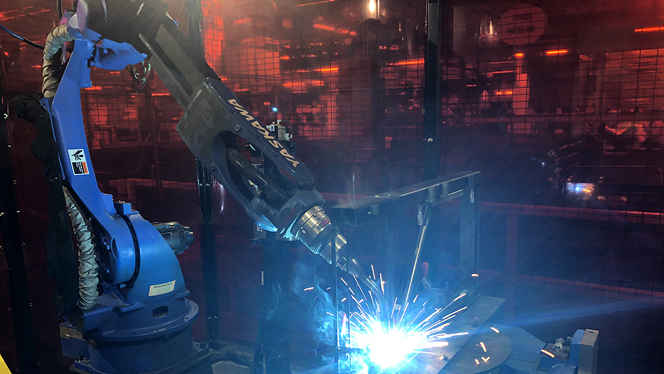

AMI Attachments uses robot automation for an advantage in weld quality and cycle time!

An ArcWorld® LC welding workcell enables greater quality, efficiency and safety for optimized operations.

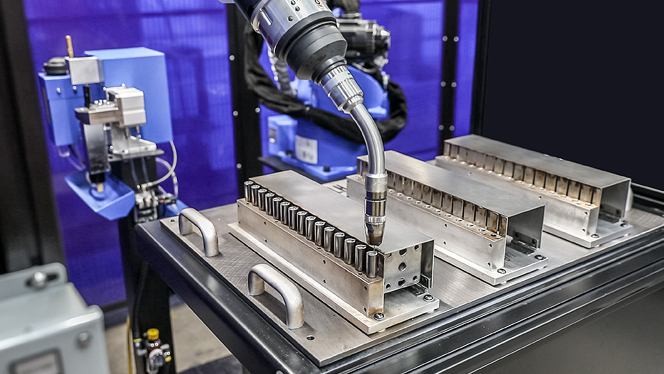

Students at eKAMI train on Yaskawa HC10 collaborative robots, preparing for work in real-world CNC shops.

Students at the USC Center for Advanced Manufacturing (CAM) learn with cutting-edge Yaskawa robots.

Extended reach GP20HL robot enables safe, efficient and affordable pavement marking for contractors, municipalities and more.

Leading powder metal products producer, GKN, leverages a plethora of robot advantages to increase throughput and reduce scrap.

Leading chassis supplier and manufacturer of vehicle brake and suspension systems, BWI Group implements fast, compact SCARA robot for end-of-line part transfer.

Food Manufacturer, IMO Foods Ltd., optimizes throughput with a GP25 robot for end-of-line packaging, while alleviating worker fatigue and maximizing floorspace.

Leading chassis supplier and manufacturer of vehicle brake and suspension systems exceeds OEM requirements for safety-critical welds with a customized ArcWorld workcell.

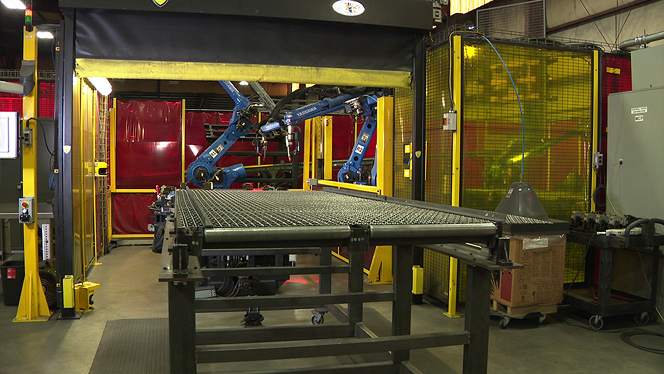

Manufacturer and supplier of mass-transportation seating products implements a custom two-station workcell for the welding of foldaway seat joints, improving quality and throughput, while bolstering their workforce.

A riser-mounted MPX1150 robot that is Factory Mutual approved for Class I, Div. 1 use in hazardous environments enables precise, consistent coating for paint performance testing.

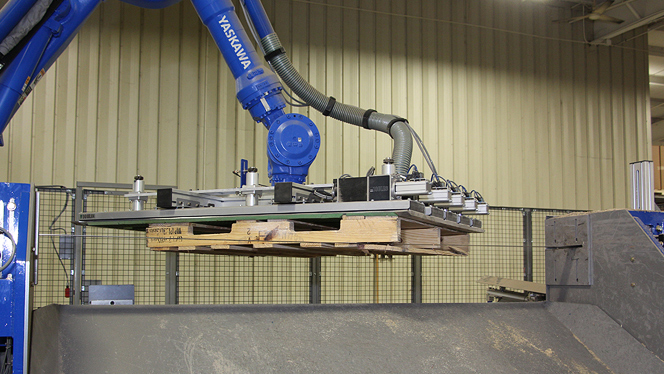

A wooden packaging products manufacturer implements a robotic bandsaw with an six-axis Yaskawa handling robot, providing the reliability needed to meet year-round production demand.

A manufacturer of premium workshop equipment for vehicle maintenance replaces inefficient robotic technology with a custom four-station welding workcell, reducing scrap and eliminating rework due to poor quality welds.

A custom robotic workcell with vision-guided robots helps a leading producer of wire partition products increase consistency and throughput, dropping cycle time by 50 percent.